Understanding Mud Pump Pistons

Oct 12, 2023

Introduction:

Mud pumps are the workhorses of drilling operations, and at the core of their operation are mud pump pistons. These unassuming yet critical components are responsible for generating the pressure necessary to circulate drilling fluids. In this blog, we'll take a closer look at mud pump pistons, their significance, and how they contribute to the success of drilling operations.

I. The Role of Mud Pump Pistons:

Mud pump pistons are essential for the circulation of drilling fluids. They perform the following crucial functions:

1. Generating Pressure:

- Mud pump pistons create the high-pressure environment required to force drilling fluids down the drill string and return cuttings to the surface.

2. Maintaining Consistent Flow:

- These pistons ensure a continuous and steady flow of drilling mud, which is vital for efficient drilling and well control.

II. Types of Mud Pump Pistons:

Mud pump pistons come in various types, with the two most common being:

1. Triplex Pistons:

- Triplex mud pumps have three pistons that work in sync to generate pressure. They are widely used in drilling operations due to their reliability and efficiency.

2. Duplex Pistons:

- Duplex mud pumps have two pistons and are commonly used for less demanding drilling tasks.

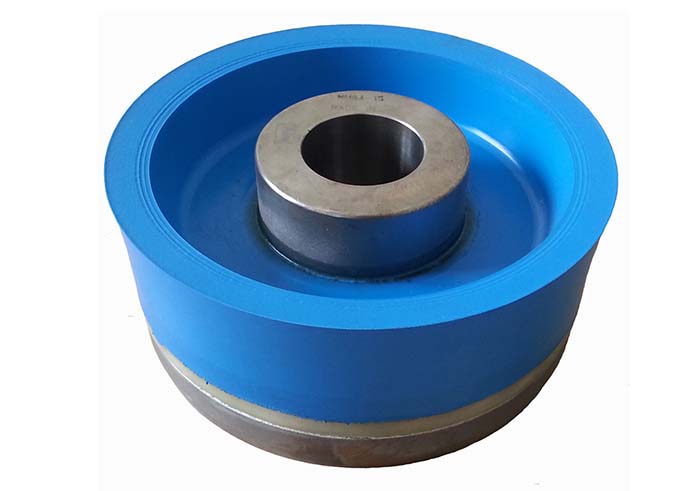

III. Materials and Design:

Mud pump pistons are designed with durability and wear resistance in mind. Key considerations include:

1. Materials:

- Pistons are typically made of robust materials like hardened steel, aluminum, or even ceramic, depending on the specific pump's requirements.

2. Design:

- Pistons often feature a replaceable wear plate to extend their lifespan. They are designed to maintain a tight seal within the pump chamber.

IV. Maintenance and Inspection:

Proper maintenance of mud pump pistons is essential for uninterrupted drilling operations. Key points to remember include:

1. Regular Inspections:

- Inspect pistons for signs of wear, damage, or leaks. Address any issues promptly to avoid pump failure.

2. Lubrication:

- Proper lubrication is necessary to reduce friction and prevent overheating. Always follow the manufacturer's recommendations for lubrication intervals.

V. Conclusion:

Mud pump pistons are the unsung heroes of drilling operations, responsible for creating the pressure needed to reach drilling depths successfully. Understanding their functions, types, materials, and the importance of regular maintenance is crucial for the efficient and safe operation of drilling equipment.

When working with mud pump pistons, always adhere to manufacturer guidelines and industry best practices. By doing so, you can ensure that these essential components continue to perform reliably, contributing to the success of your drilling projects.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported