Description

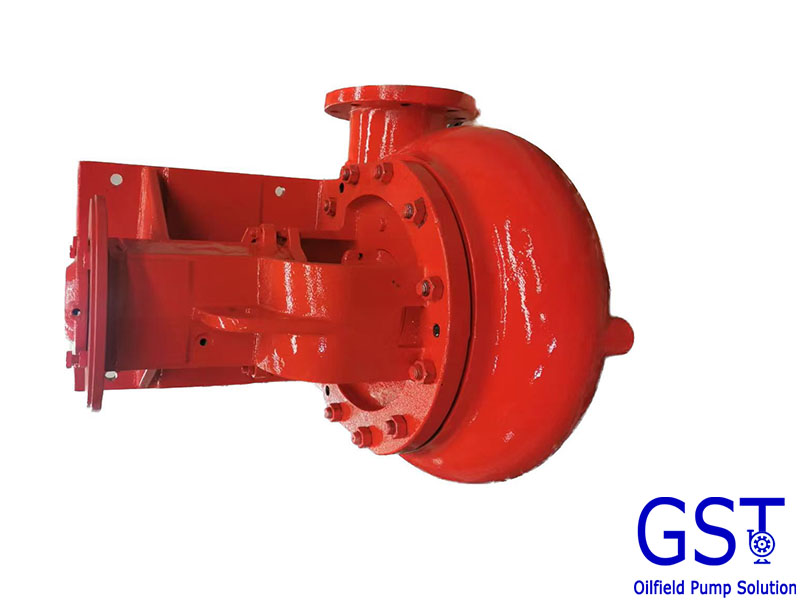

The replacement parts for centrifugal sand pumps are essential components used to maintain and repair these pumps, ensuring their continuous and efficient operation. Centrifugal sand pumps are widely used in various industries, including oil and gas, mining, dredging, and construction, for handling fluids containing abrasive materials like sand and slurry. Here's a comprehensive introduction to the replacement parts for centrifugal sand pumps:

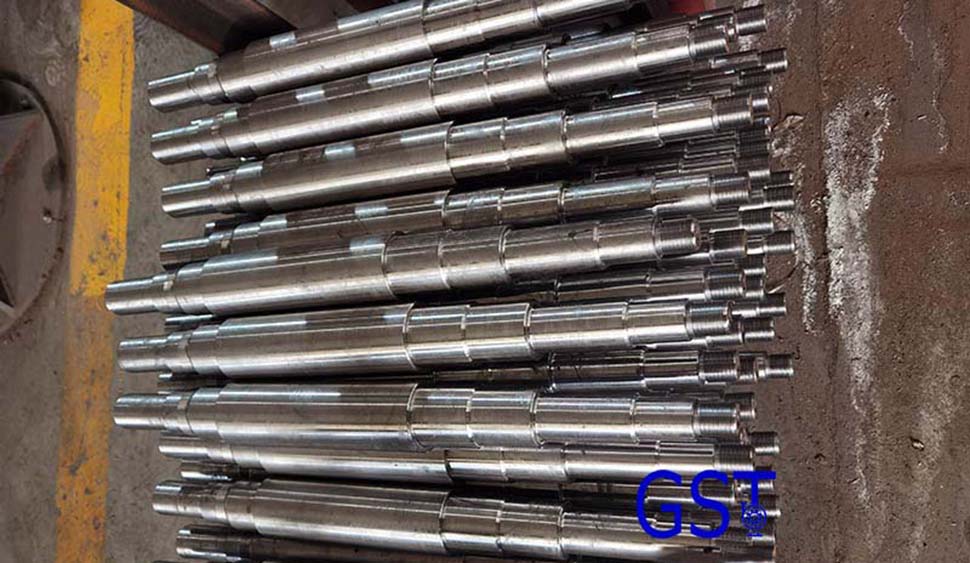

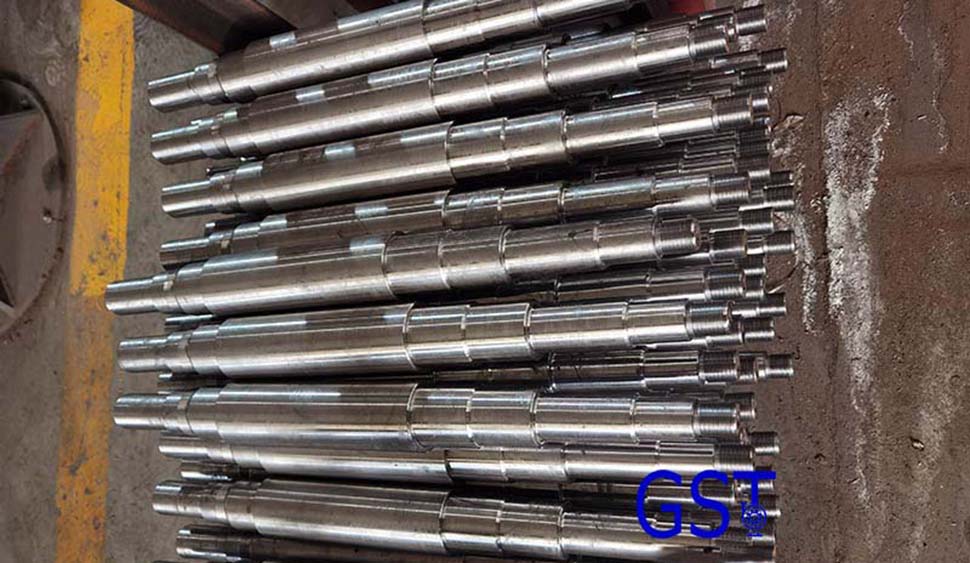

1. Sand Pump Shaft:

The pump shaft is a critical part that connects the impeller to the pump motor. It transmits the rotational force to the impeller, facilitating the pumping action. If the shaft becomes damaged or bent, it can negatively impact the pump's performance. Replacing the shaft ensures the pump's proper operation.

2. Sand Pump Bearings:

The bearings support the pump shaft, allowing it to rotate smoothly. Bearings are subjected to considerable stress and wear in sand pump applications. Regular inspection and replacement of worn bearings are essential to avoid pump failures.

3. Sand Pump Mechanical Seal:

As mentioned in the previous response, the mechanical seal prevents fluid leakage between the pump shaft and casing. Replacing the mechanical seal when it shows signs of wear or leaks is crucial to maintain the pump's integrity and prevent environmental contamination.

4. O-Rings, oil seal and Gaskets:

O-rings and gaskets are essential for creating a proper seal and preventing leaks between various pump components. These components are susceptible to wear and damage over time and should be replaced during routine maintenance.

5. Mechanical Seal Stuffing Box:

The main purpose of the stuffing box is to accommodate the mechanical seal and create a confined space around the pump's shaft. It ensures that the fluid being pumped stays inside the pump and does not leak along the shaft, reducing wastage and preventing environmental contamination.

Packaging & Shipment

Packaging type: Export wooden box

Exporting port: Tianjin, Shanghai

FAQ

1. Who are you?

Tianjin Geostar Petroleum Equipment Co., Ltd. are integrated oilfield pump solution provider. We produce GST brand centrifugal pump and supply RG brand F series drilling mud pump, parts, plunger pump etc.

2. Why should we buy from you?

a. Competitive price

b. Quick delivery

c. Worry free after-sales service. Refund or sending new goods if quality issues can't be resolved by after-sales service.

3. Is after-sale service available to your products?

Yes, we have professional after-sale service team which will offer you the site commissioning service. Engineers are available to be abroad for service.

4. What is your warranty policy?

We offer 12 months limited warranty for complete set of equipment or machinery.

5. What is the delivery time for your product?

Generally, ready stock for commonly used parts, mud pump unit and complete equipment depends upon technical configuration.

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported