Description

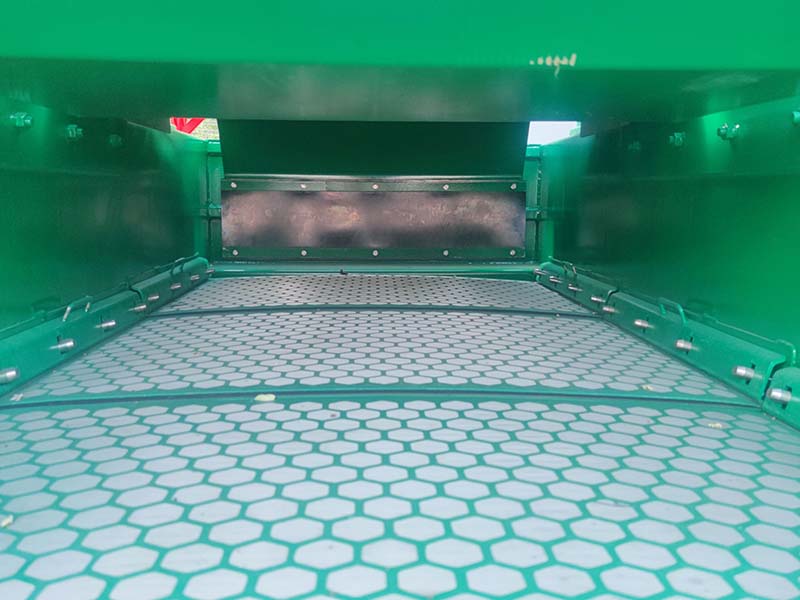

A shaker screen is a vital component in the process of solids control within the drilling industry. It is utilized as part of a shale shaker, which is a primary device used to separate drilling cuttings from drilling fluid, also known as drilling mud. Shaker screens play a crucial role in maintaining drilling efficiency, reducing costs, and ensuring environmental compliance.

Key Features of Shaker Screens:

1. **Particle Separation**: Shaker screens work by using a vibrating motion to separate solid particles, such as cuttings, from the drilling fluid. The screens consist of mesh panels with different-sized openings, allowing finer particles to pass through while retaining larger particles.

2. **Screen Mesh**: Shaker screens are available in various mesh sizes, which determine the size of particles that can be separated. Different drilling operations and formations require specific mesh sizes to achieve optimal separation efficiency.

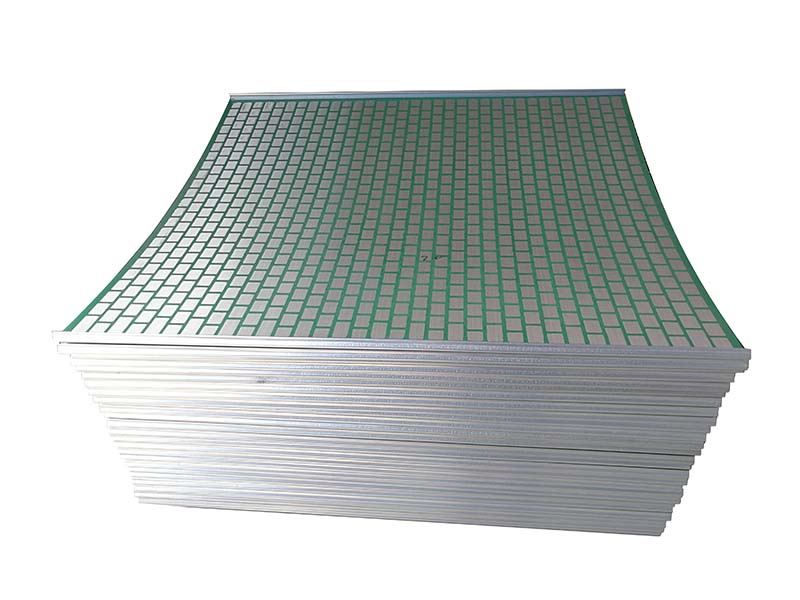

3. **Performance and Efficiency**: The quality and design of shaker screens significantly impact their performance. High-quality screens with durable materials and precise manufacturing ensure efficient separation, longer lifespan, and reduced maintenance.

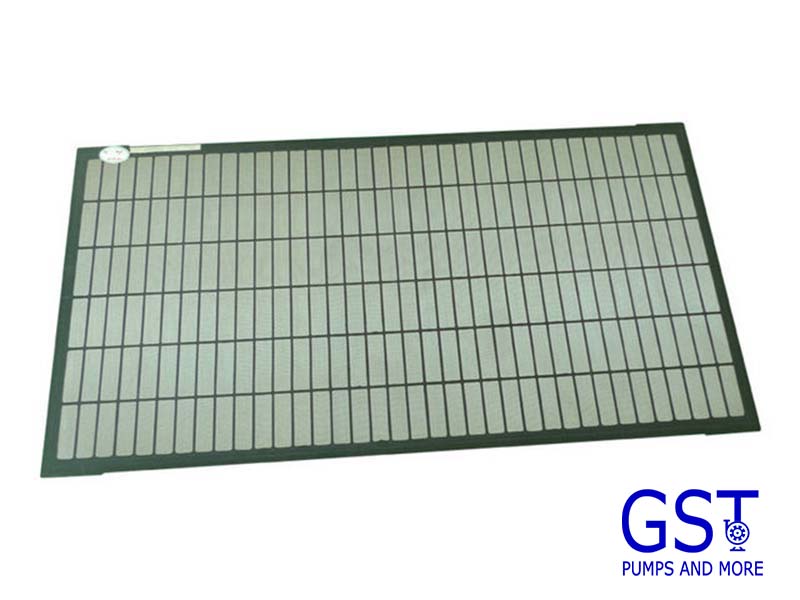

4. **Screen Panel Configuration**: Shaker screens come in various configurations, such as flat panels or pretensioned screens. The choice depends on factors like the shaker model, fluid capacity, and operational requirements.

5. **Screen Types**: There are different types of shaker screens, including framed screens, hook-strip screens, and pretensioned screens. Each type has its advantages and is selected based on the drilling operation's needs.

Benefits of Using Quality Shaker Screens:

1. **Improved Drilling Fluid Quality**: Efficient shaker screens help remove solid particles from the drilling fluid, maintaining its properties and ensuring consistent performance throughout the drilling process.

2. **Reduced Environmental Impact**: Proper solids control using shaker screens minimizes the discharge of cuttings-laden drilling mud, reducing environmental impact and complying with regulations.

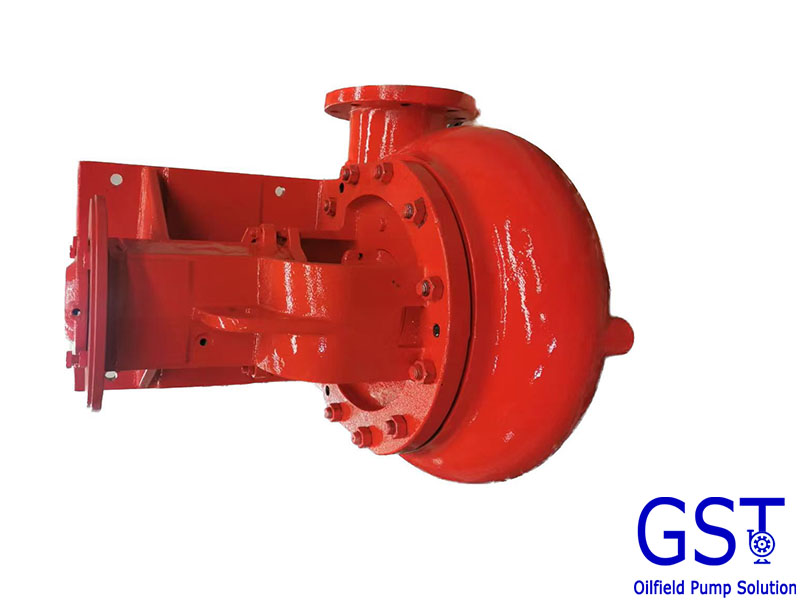

3. **Enhanced Equipment Lifespan**: Effective solids separation prevents excessive wear on downstream equipment, such as pumps and mud tanks, extending their lifespan and reducing maintenance costs.

4. **Cost Savings**: By separating valuable drilling fluid from cuttings, shaker screens help reduce the volume of drilling waste that requires disposal, leading to cost savings.

5. **Operational Efficiency**: Reliable shaker screens reduce downtime caused by equipment failures and allow drilling operations to proceed smoothly and efficiently.

In conclusion, shaker screens are essential components in the solids control process within the drilling industry. Choosing high-quality screens and maintaining them properly contributes to improved drilling efficiency, environmental compliance, and cost savings. As drilling operations become more sophisticated, the role of shaker screens in maintaining drilling fluid integrity becomes increasingly critical.

Applications

- Flat screens can replace Derrick FLC500, FLC2000, FLC313M, ALS etc.

- Frame screens can replace MI-SWACO Mongoose, NOV brand Cobra etc.

- Composite screen can replace MI-SWACO Mongoose, NOV brand Cobra etc.

Specifications

|

API mesh No.

|

Separation range, μm

|

API mesh No

|

Separation range, μm

|

|

API 10

|

1850-2180

|

API 100

|

137.5-165

|

|

API 20

|

780-925

|

API 120

|

116.5-137.5

|

|

API 30

|

550-655

|

API 140

|

98-116.5

|

|

API 35

|

462-550

|

API 170

|

82.5-98

|

|

API 40

|

390-462

|

API 200

|

69-82.5

|

|

API 50

|

275-390

|

API 230

|

58-69

|

|

API 60

|

213-275

|

API 270

|

49-58

|

|

API 70

|

196-213

|

API 325

|

41.5-49

|

|

API 80

|

165-196

|

API 400

|

35-41.5

|

Packaging & Shipment

Packaging type: Export Plywood Box

Exporting port: Tianjin, Shanghai

FAQ

1. Who are you?

Tianjin Geostar Petroleum Equipment Co., Ltd. are integrated oilfield pump solution provider. We produce GST brand centrifugal pump and supply RG brand F series drilling mud pump, parts, plunger pump etc.

2. Why should we buy from you?

a. Competitive price

b. Quick delivery

c. Worry free after-sales service. Refund or sending new goods if quality issues can't be resolved by after-sales service.

3. Is after-sale service available to your products?

Yes, we have professional after-sale service team which will offer you the site commissioning service. Engineers are available to be abroad for service.

4. What is your warranty policy?

We offer 12 months limited warranty for complete set of equipment or machinery.

5. What is the delivery time for your product?

Generally, ready stock for commonly used parts, mud pump unit and complete equipment depends upon technical configuration.

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported