What is a mud pump ceramic liner?

Sep 05, 2025

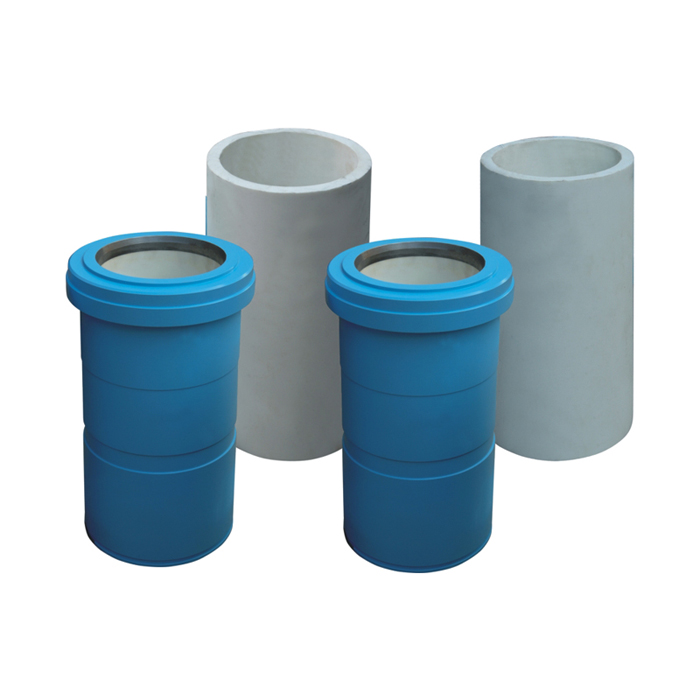

The mud pump ceramic liner is an improved version of the insert-type mud pump bi-metal liner, where the corrosion-resistant ceramic inner sleeve replaces the high-chromium alloy cast iron inner sleeve. Its technical principle lies in the application of modern phase transformation toughening technology, using high-toughness and high-strength toughened oxide ceramic materials to manufacture the integral inner sleeve of the liner—meeting the requirement for long service life. The production process of the outer sleeve is identical to that of the outer sleeve of bi-metal liners.

Ⅰ. Materials of Ceramic Liners

As the scope of global oil and gas resource exploitation continues to expand, frequent replacement of a large number of metal liners still fails to meet the high-pressure and anti-wear requirements of drilling rigs. However, ceramic liner materials—such as zirconia, alumina, and ZTA (Zirconia Toughened Alumina) composite ceramics—boast extremely high hardness, far exceeding that of metal materials.

The raw materials (high-purity zirconia and alumina micropowders) undergo advanced cold pressing for one-time forming, high-temperature sintering, assembly, and final high-precision grinding and polishing. The resulting ceramic liners exhibit high flexural strength, high tensile strength, high fracture toughness, and excellent acid and alkali corrosion resistance.

Ⅱ. Product Features of Ceramic Liners

1. Excellent Corrosion Resistance

Ceramic materials have extremely high chemical stability and are less prone to chemical reactions in harsh environments such as acid, alkali, and salt spray. Neither chloride ions/hydrogen ions in drilling fluid nor acidic slurry in mining scenarios can easily cause corrosion damage to ceramic liners. For example, when handling drilling fluid with a pH value of 3-11, ceramic liners can maintain structural integrity for a long time; in contrast, bi-metal liners may suffer from wall thickness reduction and seal failure due to corrosion within a few months.

2. Good High-Temperature Resistance and Thermal Stability

Ceramic materials have high melting points (e.g., approximately 2050℃ for alumina and 2715℃ for zirconia) and low thermal expansion coefficients, so they are not prone to deformation or cracking in high-temperature environments. During drilling operations, the local temperature generated by friction during pump operation may reach 150-200℃; ceramic liners can maintain dimensional stability, avoiding increased sealing gaps caused by thermal expansion and contraction. In contrast, metal liners are prone to thermal deformation at high temperatures, which may lead to drilling fluid leakage and reduced pump efficiency.

3. Low Friction and Energy-Saving Properties

Ceramic materials have a high surface smoothness and an extremely low friction coefficient with pistons or plungers. For instance, the F-type mud pump ceramic liners feature a uniformly structured ceramic inner lining; their surfaces undergo multiple precision processing steps, resulting in excellent finish and gloss. This characteristic reduces frictional resistance between the liner and moving parts, lowering the power consumption of mud pumps—typically achieving an energy-saving effect of 5%-10%. Meanwhile, it further delays component aging and improves the operational stability of the entire equipment.

Ⅲ. Comprehensive Cost

Compared with traditional bi-metal liners, the service life of ceramic liners can reach 3000-4000 hours—more than 10 times longer than that of metal liners. This significantly improves cost-effectiveness, reduces comprehensive costs (including maintenance, labor, storage, and transportation), and ensures the stable progress of drilling operations.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported