What are the different types of mud pump liners?

Feb 28, 2025

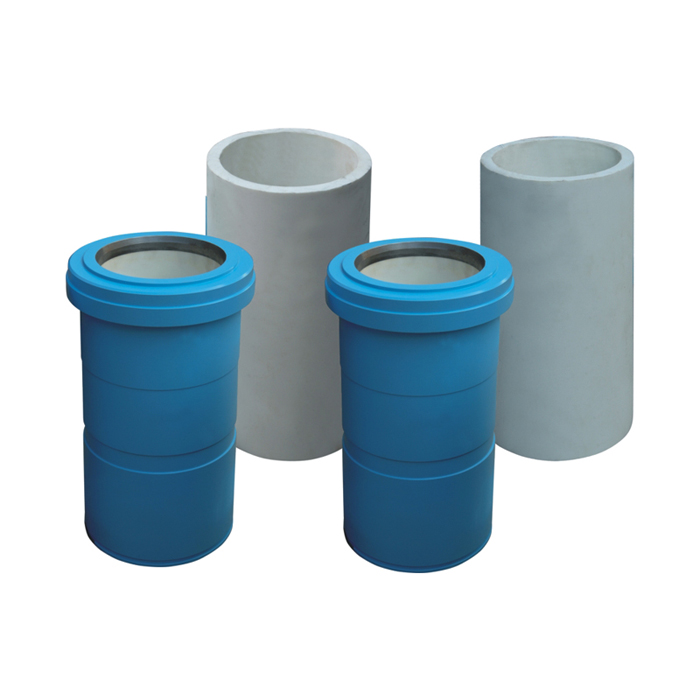

The liners of mud pumps include bi-metal liners and ceramic liners, each having its own characteristics. Below, we will introduce these two types of liners in detail from the following aspects.

Ⅰ. Bi-Metal Liners of Mud PumpsThe Bi-Metal liner is a cylinder liner composed of two different metallic materials and is widely applied in the industrial field. The following is a detailed introduction to it:Advantages

Good Wear Resistance: Usually, the inner layer is made of high-hardness wear-resistant alloys, such as high-chromium cast iron. These materials have high hardness and can effectively withstand the erosion and wear of materials, making them suitable for use when transporting media containing solid particles.

High Strength and Toughness: The outer layer of metal generally uses steel with higher strength, such as carbon steel, which provides good mechanical strength and toughness, enabling the cylinder liner to withstand greater pressure and impact loads. In some working conditions with complex situations and large impact forces, the Bi-Metal liner can ensure the normal operation of the equipment.

Good Corrosion Resistance: The inner layer of some bi-metal liners uses metallic materials with better corrosion resistance, such as stainless steel. This allows the cylinder liner to resist the erosion of corrosive media like acids and alkalis to a certain extent, making it suitable for transporting liquids with a certain degree of corrosiveness.

High Cost-effectiveness: Compared with some high-performance liners made of a single material (such as pure ceramic liners), the bi-metal liner reduces costs by reasonably combining two metallic materials while meeting certain performance requirements. For some projects that are sensitive to costs, the bi-metal liner is an economical and practical choice.

Strong Repairability: During the use process, if the liner suffers from local wear or damage, since it is mainly composed of metallic materials, it can be repaired through metal processing techniques such as surfacing and repair welding. The repair cost is relatively low, and the operation is relatively simple, which can effectively extend the service life of the equipment and reduce the frequency of equipment replacement.Manufacturing Process

Centrifugal Casting of the Inner Sleeve: Pour the molten high-chromium cast iron liquid into a high-speed rotating mold. Under the action of centrifugal force, the iron liquid adheres evenly to the inner wall of the mold, and after cooling, the inner sleeve is formed. This process can make the inner sleeve have a dense structure without shrinkage cavities, air holes, and other defects, ensuring the quality and performance of the inner sleeve.

Hot Pressing Molding of the Outer Sleeve: Heat the high-quality carbon steel billet to an appropriate temperature, put it into the mold, and perform one-time hot pressing molding through a press to make the outer sleeve reach the required size and shape, obtaining good strength and toughness.

Insertion and Assembly: Insert and assemble the processed inner sleeve and outer sleeve. Usually, an interference fit method is adopted to make the two combine closely to form an integral bi-metal liner to meet the usage requirements of the mud pump.Application Scenarios

In the Petroleum Drilling Field: In onshore petroleum drilling, it is used for drilling operations in ordinary formations and can withstand conventional mud pressure and wear. On offshore petroleum drilling platforms, it can also meet the operation requirements to a certain extent, providing a reliable channel for the circulation and transportation of mud.

Ⅱ. Ceramic Cylinder Liners of Mud PumpsCeramic liners are widely used in the industrial field. The following is a detailed introduction to them:Advantages

High Wear Resistance: Ceramic materials have extremely high hardness. For example, alumina ceramics, zirconia ceramics, etc., have a Mohs hardness of about 9, second only to diamond. This enables the ceramic liner to effectively resist the wear caused by solid particles, fluid erosion, etc. In working conditions where highly abrasive media such as mineral slurries, coal powders, and sand and gravel are transported, it shows excellent wear resistance and greatly extends the service life of the equipment.

Excellent Corrosion Resistance: Ceramics have good chemical stability and hardly react with chemical substances such as acids, alkalis, and salts. Therefore, the ceramic liner can remain stable in a strongly corrosive environment. Using a ceramic liner can effectively prevent the equipment from being corroded and ensure the safe and stable operation of production.

Good High-temperature Resistance: Many ceramic materials have a high melting point and good thermal stability, and can maintain their physical and chemical properties in a high-temperature environment.

Smooth Surface and Low Friction Coefficient: The surface of the ceramic liner is extremely smooth, and the friction coefficient is much lower than that of other materials such as metals. This significantly reduces the resistance when the fluid flows in the pipeline, not only improving the transportation efficiency but also reducing energy consumption. At the same time, the smooth surface also reduces the adhesion and accumulation of materials on the inner wall of the pipeline, which is beneficial to keeping the pipeline unobstructed.There are also mud pump ZTA liners and pure zirconia cylinder liners among ceramic cylinder liners. The following introduces the characteristics of these two types of ceramic cylinder liners.

Ⅲ. ZTA Ceramic Cylinder LinersManufacturing Process

Batching and Mixing: Accurately weigh raw materials such as alumina and zirconia in a certain proportion, add additives, and put them into a ball mill for uniform mixing to form a uniform green body.

Molding: Use methods such as dry pressing molding and isostatic pressing molding to form the mixed raw materials into a green body of the required shape.

Sintering: Put the green body into a high-temperature furnace for sintering. At a high temperature of 1600-1800°C, the raw materials undergo a solid-phase reaction to form a dense ZTA ceramic.

Processing and Assembly: Cut, grind, polish, and perform other processing on the sintered ceramic to make it reach the required size and accuracy, and then use the vulcanization process to composite and assemble the ZTA ceramic with rubber, steel plates, etc.Advantages Compared with Other Cylinder LinersCompared with ordinary alumina ceramic liners, ZTA ceramic liners have better toughness and impact resistance and a longer service life. Compared with metallic liners, ZTA ceramic liners have higher hardness, wear resistance, and corrosion resistance, and can maintain good performance under harsh working conditions, reducing equipment maintenance and replacement costs.

Ⅳ. Pure Zirconia Cylinder LinersIt refers to a liner mainly made of zirconia, and its zirconia content is usually above 95%. The following is a detailed introduction:Material Characteristics

High Purity: The main component is zirconia, and the purity is generally above 95%. A small amount of stabilizers, such as yttria, may be added to improve its performance.

High Density: It has a relatively high density, generally about 6.0 grams per cubic centimeter.

Stable Chemical Properties: It has excellent chemical stability and can withstand the corrosion of various acids, alkalis, and other chemical substances.Performance Advantages

Good Wear Resistance: It has excellent wear resistance and can effectively resist the erosion and wear of solid particles in the medium, extending the service life of the equipment.

High Temperature Resistance: It can withstand a high temperature of up to 800°C and has good thermal stability.

Strong Corrosion Resistance: It has excellent tolerance to various corrosive media and can maintain stable performance in a harsh chemical environment.

Good Electrical Insulation: It has good electrical insulation performance and can be used in some occasions where electrical insulation is required.Manufacturing Process

Raw Material Preparation: Select high-purity zirconia powder as the main raw material, and a small amount of additives can be added according to needs. Uniformly mix the raw materials through ball milling to prepare the required powder material.

Processing: Cut, grind, polish, and perform other processing on the sintered zirconia cylinder liner to make its size and accuracy reach the required standards.Application Scenarios

In Petroleum and Natural Gas Drilling: In the mud pumps for petroleum and natural gas drilling operations, it can withstand the erosion of high-pressure mud and solid particles.Cost and Service Life

High Cost: Due to the high cost of raw materials and the complex manufacturing process, the production cost of pure zirconia liners is relatively high, and their price is also more expensive than that of some ordinary liners.

Long Service Life: With its excellent performance, the service life of pure zirconia liners is relatively long.

Ⅴ. Comparison between Ceramic Cylinder Liners and Bi-Metal Liners of Mud PumpsCeramic liners and metallic bi-metal liners of mud pumps each have their own advantages and applicable scenarios. The following is a comparative analysis from multiple aspects:

1.Wear Resistance

Ceramic Cylinder Liners: Ceramic materials have extremely high hardness. For example, alumina ceramics, zirconia ceramics, etc., and their wear resistance is usually much better than that of metallic materials. Taking zirconia ceramics as an example, it can effectively resist the erosion and wear of solid particles in the mud. For mud containing a large number of sharp and high-hardness particles, the wear rate of the ceramic liner is very slow, and the service life is long.

Bi-metal Cylinder Liners: Wear-resistant metallic materials such as high-chromium cast iron also have good wear resistance, but there is still a gap compared with ceramics. When transporting highly abrasive mud for a long time, the wear of the bi-metal liner is relatively fast, and the liner needs to be replaced more frequently, increasing the maintenance cost and downtime.

2.Corrosion Resistance

Ceramic Cylinder Liners: Ceramics have good chemical stability and hardly react with chemical substances such as acids and alkalis. When transporting strongly corrosive mud, they can maintain the integrity and performance stability of the liner.

Bi-metal Liners: Some bi-metal liners (such as duplex stainless white iron, etc.) have a certain degree of corrosion resistance, but in a strongly corrosive environment, the metal may still corrode, leading to the damage to the liner. Even metallic materials with better corrosion resistance are difficult to compare with ceramics in terms of corrosion resistance.

3. Strength and Toughness

Mud Pumps with Ceramic Liners: The disadvantage of ceramic materials is that their toughness is relatively low and they are more brittle. When subjected to large impact loads, the ceramic liner may crack or even break. Although some ceramic toughening technologies have developed in recent years, the toughness of ceramics is still not as good as that of metals. In working conditions where the mud pump may encounter large impact forces, the reliability of the ceramic liner will be affected to a certain extent.

Mud Pumps with Bi-Metal Liners: Metallic materials have good strength and toughness and can withstand large impacts and pressures. In some working conditions with complex situations and possible large impact forces, such as when the drilling mud pump works in an unstable formation, the bi-metal liner can better adapt to such working conditions and reduce the risk of damage caused by impacts.

4. Cost

Ceramic Liners: Due to the relatively high price of ceramic materials themselves and the relatively complex manufacturing process, the initial purchase cost of mud pumps with ceramic liners is relatively high. In addition, due to the high requirements for the processing and installation of ceramic liners, the maintenance cost is also relatively high.

Bi-Metal Liners: The manufacturing cost of bi-metal liners is relatively low, and the processing and maintenance technologies of metallic materials are relatively mature, and the maintenance cost is also low.

5. Applicable Working Conditions

Ceramic Liners: They are more suitable for use in working conditions with high abrasion, high corrosion, high requirements for the purity of the mud (ceramics are not likely to contaminate the mud), but with small impact loads.

Bi-Metal Liners: They are suitable for working conditions with more complex situations, possible large impact loads, and where the requirements for wear resistance and corrosion resistance are not extremely high.

6.Service Life

Bi-Metal Liners: Under normal working conditions, the service life is generally more than 800 hours.

Zirconia Ceramic Liners: It has a relatively long service life, usually reaching more than 4,000 hours, which is several times that of the bimetallic cylinder liner.

In conclusion, if the working conditions are mainly characterized by high abrasion and high corrosion with small impact loads, the ceramic liner is a better choice; while if the working conditions are complex, with large impact loads and a sensitivity to costs, the bi-metal liner is more appropriate.Cylinder liners for models like F1000 mud pump liner and F1600 mud pump liner are available in various materials.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported