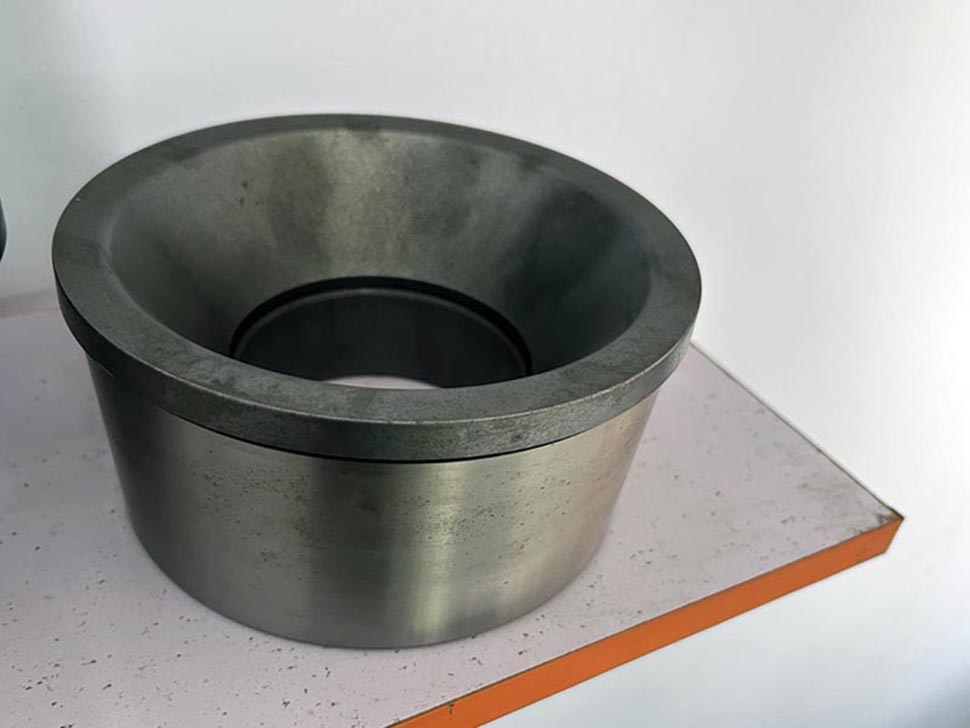

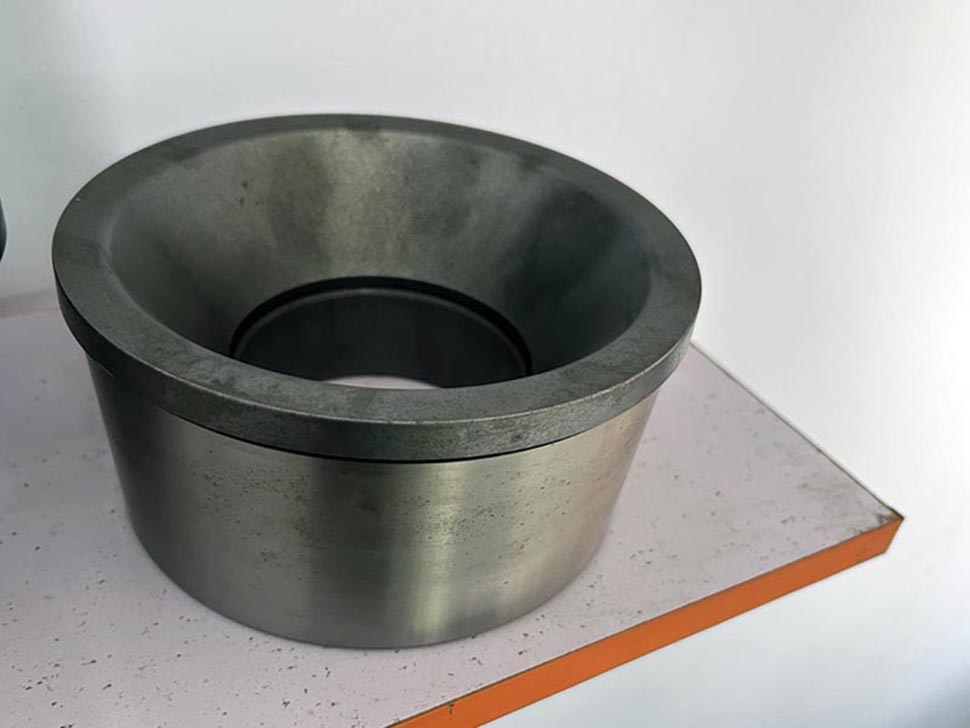

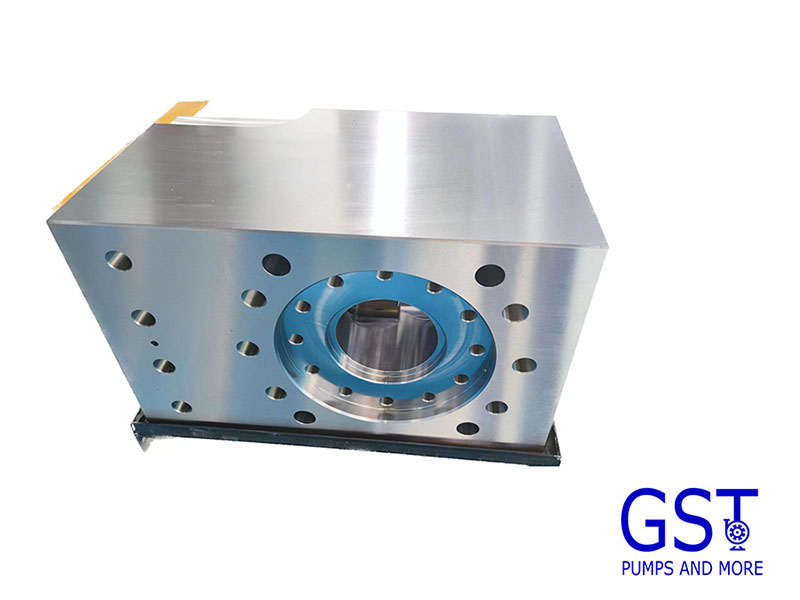

The Role of Mud Pump Valve Seats:

Mud pump valve seats serve as the sealing interface within the pump, preventing the undesired backflow of drilling mud. This functionality is essential for maintaining the integrity of the drilling process, ensuring that mud circulates effectively and that pressure is maintained as required.

Design Features:

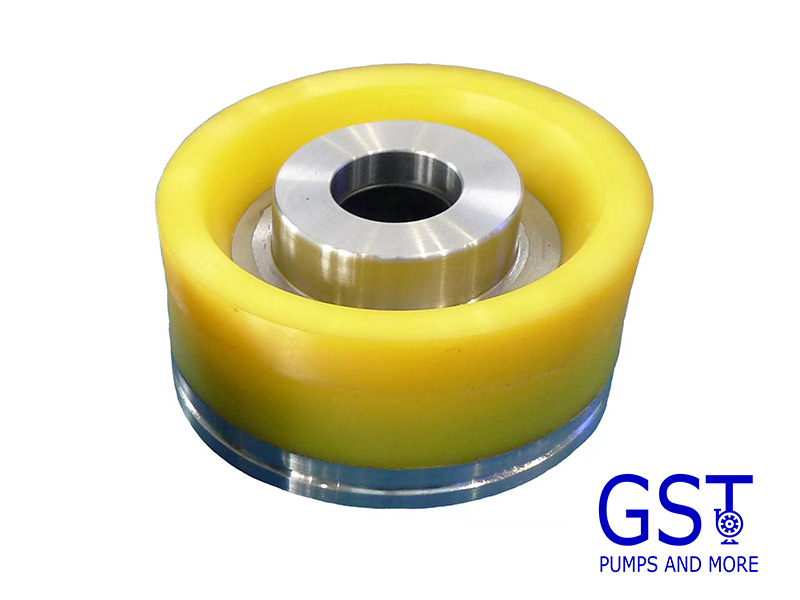

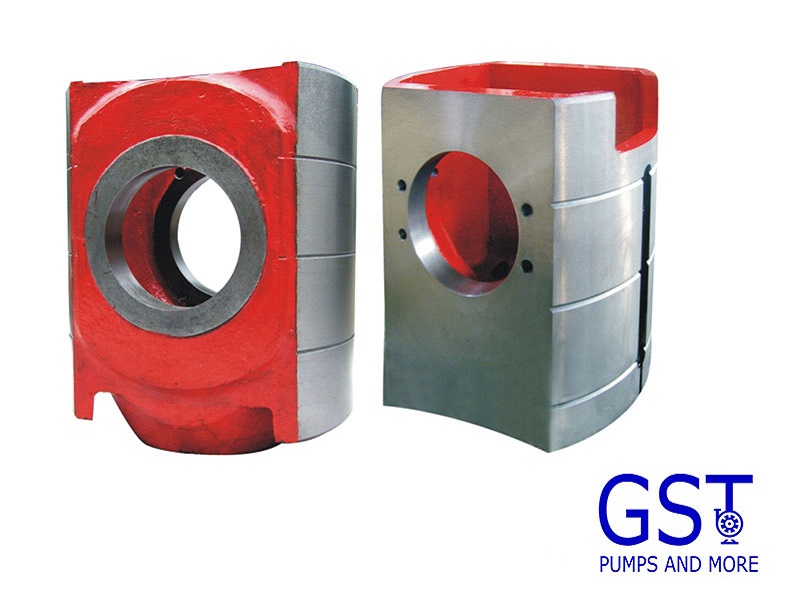

Valve seats are meticulously designed to withstand the harsh conditions encountered during drilling. Typically crafted from forged steel, these seats are engineered to resist abrasion and erosion caused by the abrasive nature of drilling mud. The design prioritizes longevity, contributing to the overall reliability of the mud pump.

Material Selection:

The choice of materials for valve seats is critical to their performance. Premium forged steel are commonly selected for their resilience and resistance to wear. These materials can endure the constant pounding and abrasive effects of drilling mud, ensuring that the valve seats maintain their sealing capabilities over extended periods.

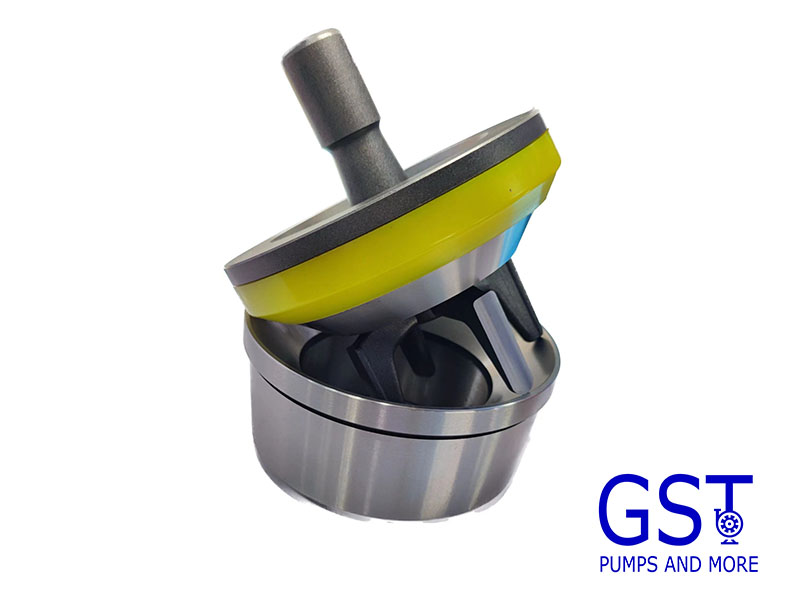

Efficiency and Pump Longevity:

The efficiency of a mud pump heavily relies on the functionality of its valve seats. Effective sealing provided by these seats enables the pump to maintain consistent pressure levels, allowing for smooth mud circulation. This not only enhances the drilling process but also contributes to the longevity of the pump itself, reducing maintenance requirements.

Maintenance Considerations:

While mud pump valve seats are designed for durability, periodic inspection and maintenance are still necessary. Regular checks ensure that the seats remain in optimal condition, and any signs of wear or damage can be addressed promptly, preventing potential issues during drilling operations.

Conclusion:

In the realm of drilling operations, the mud pump valve seat emerges as a silent hero, playing a vital role in maintaining the efficiency and reliability of the pump. Through thoughtful design and material selection, these valve seats contribute to the seamless circulation of drilling mud, ultimately enhancing the overall success of drilling endeavors.

Packaging & Shipment

Packaging type: Export Plywood Box

Exporting port: Tianjin, Shanghai

FAQ

1. Who are you?

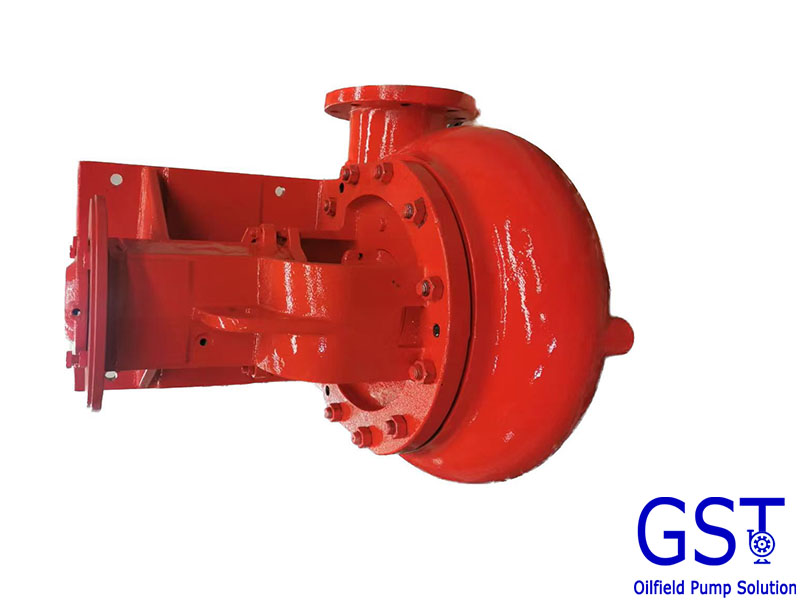

Tianjin Geostar Petroleum Equipment Co., Ltd. are integrated oilfield pump solution provider. We produce GST brand centrifugal pump and supply RG brand F series drilling mud pump, parts, plunger pump etc.

2. Why should we buy from you?

a. Competitive price

b. Quick delivery

c. Worry free after-sales service. Refund or sending new goods if quality issues can't be resolved by after-sales service.

3. Is after-sale service available to your products?

Yes, we have professional after-sale service team which will offer you the site commissioning service. Engineers are available to be abroad for service.

4. What is your warranty policy?

We offer 12 months limited warranty for complete set of equipment or machinery.

5. What is the delivery time for your product?

Generally, ready stock for commonly used parts, mud pump unit and complete equipment depends upon technical configuration.

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported