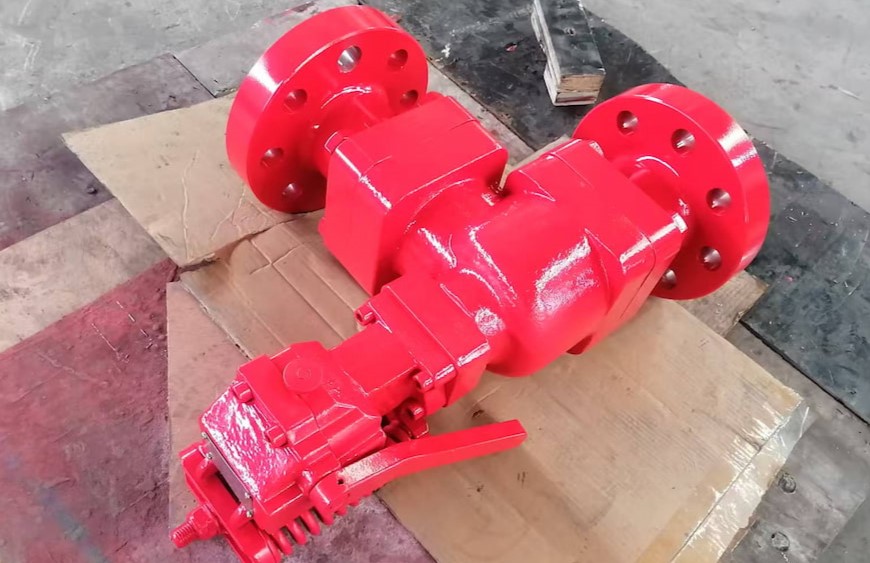

Understand the spring reset relief valve used in oil drilling

Mar 26, 2025

The spring reset relief valve is a safety protection device applied in the field of oil drilling. The following is a detailed introduction from aspects such as structure, working principle, characteristics, and maintenance:

Ⅰ. Structure

Valve Body: It serves as the outer shell of the relief valve. Usually, it is made of materials such as cast steel, cast iron, or stainless steel, and has sufficient strength and sealing performance to withstand the working pressure of the system. Inside the valve body, there is a piston installed to control the connection or disconnection between the inlet joint assembly and the outlet joint assembly. A valve cap is set at the upper end of the valve body. Inside the valve cap, there is a connecting rod, and a reset handle is arranged on the outer side of the valve cap. The lower end of the connecting rod is connected to the piston to control the movement of the piston, and the upper end of the connecting rod is connected to the force application point of the reset handle.

Valve Spring: It is the component that provides the reset force and is generally made of high-quality spring steel. The stiffness and pre-tightening force of the spring are designed and adjusted according to the working pressure and discharge capacity requirements of the relief valve.

Adjustment Mechanism: It is used to adjust the opening pressure and reseating pressure of the relief valve. Through the adjustment mechanism, the relief valve can be precisely adjusted and set according to the actual working pressure and safety requirements of the system.

Sealing Elements: They are installed between the valve core and the valve body, as well as at other connection parts, to ensure the tightness of the valve when it is closed and prevent the leakage of the medium. The sealing elements are usually made of materials such as rubber and polytetrafluoroethylene.

Ⅱ. Working Principle

Opening Process: When the system pressure rises to exceed the pressure value corresponding to the pre-tightening force of the spring, the force exerted by the medium pressure on the valve core is greater than the spring force, and the valve core is pushed open. The relief valve opens, and the medium is discharged through the valve, thereby reducing the system pressure.

Closing Process: As the system pressure decreases, when the force exerted by the medium pressure on the valve core is less than the spring force, the spring pushes the valve core to reset, and the relief valve closes, stopping the discharge of the medium.

Ⅲ. Characteristics

Automatic Reset: After the system pressure returns to normal, it can automatically reset by relying on the force of the spring without manual intervention, ensuring the normal operation of the system.

Stable Opening Pressure: By precisely adjusting the pre-tightening force of the spring, the relief valve can be accurately opened at the set opening pressure, with high pressure control accuracy.

Simple Structure: Compared with other types of relief valves, the spring reset relief valve has a relatively simple structure, which is easy to manufacture, install, and maintain, and has a lower cost.

Wide Application Range: According to different working media, pressure, and temperature requirements, spring reset relief valves of different materials and specifications can be selected, making them suitable for a variety of industrial occasions.

Ⅳ. Maintenance

Regular Inspection: During the oil drilling operation, the spring reset relief valve should be regularly inspected visually. Check whether there are abnormal conditions such as wear, corrosion, and deformation of components like the valve body, valve core, and spring. Check whether there is any leakage of the sealing elements. At the same time, check whether the adjustment mechanism is flexible to ensure that the relief valve can work properly.

Pressure Test: Conduct a pressure test on the relief valve according to the specified cycle to verify whether its opening pressure and reseating pressure meet the set values. The test can be carried out on-site using special testing equipment or the relief valve can be sent to a professional testing institution for calibration. If the pressure deviation is found to exceed the allowable range, adjustments and repairs should be carried out in a timely manner.

Cleaning and Lubrication: Regularly clean the relief valve to remove oil stains, impurities, drilling fluid, and other dirt on the surface and inside of the valve body, preventing them from entering the valve core and sealing parts and affecting the performance of the valve. At the same time, properly lubricate the moving parts such as the spring and the adjustment mechanism with high-temperature and oil-resistant lubricants to ensure the flexible movement of the parts and reduce wear.

Replacement of Components: According to the usage situation of the relief valve and the wear degree of the components, promptly replace the damaged or aged components, such as springs, sealing elements, and valve cores. For relief valves that are frequently used or in harsh working environments, the replacement cycle of components should be appropriately shortened to ensure the reliability and safety of the relief valve.

Installation and Maintenance

Installation Requirements: The relief valve must be installed vertically and directly on the joint of the container or pipeline. The inner diameter of the joint should not be smaller than the inlet diameter of the relief valve. A suitable expansion joint must be installed at the outlet of the relief valve to prevent the thermal expansion of the discharge pipe from imposing undue thermal stress on the relief valve.

Maintenance Key Points: In addition to the regular inspection, pressure test, cleaning and lubrication, and component replacement mentioned above, it should also be noted that after each maintenance, the performance of the relief valve should be tested and verified to ensure its normal operation. At the same time, detailed maintenance records should be kept, including information such as maintenance time, content, and replaced components, so as to track and analyze the usage situation and maintenance history of the relief valve.

Faults and Solutions

Leakage: It may be caused by reasons such as damaged sealing elements, worn valve cores, or impurities in the valve seat. The solutions include replacing the sealing elements, repairing or replacing the valve cores, and cleaning the valve seat.

Inaccurate Opening Pressure: The reasons may include spring fatigue, looseness or damage of the adjustment mechanism, etc. It can be solved by replacing the spring, adjusting or repairing the adjustment mechanism.

Failure to Reset in a Timely Manner: It may be caused by reasons such as spring jamming, valve core sticking, or improper setting of the reseating pressure. It is necessary to check the movement of the spring and the valve core, adjust the reseating pressure, and carry out repairs or replace components if necessary.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported