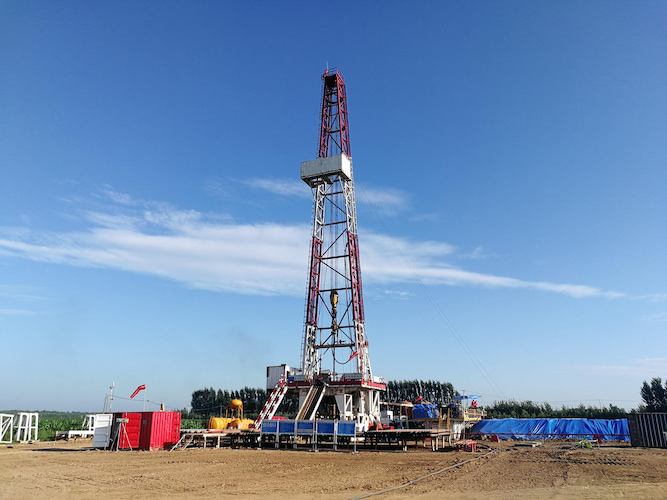

What is a vertical well in oil and gas drilling?

Sep 12, 2025

Based on the geological, geographical conditions and engineering requirements of oil and gas exploration and development, wells are divided into two main types: vertical wells and directional wells. These two are core well types in the oil and gas drilling field, with the latter further categorized into conventional directional wells, horizontal wells, cluster wells, etc. The core difference between them lies in whether the wellbore trajectory is perpendicular to the ground, and they also differ significantly in design purposes, technical characteristics, application scenarios and construction difficulty. Next, we will discuss vertical wells.

Ⅰ. Vertical Wells

In drilling engineering terminology, a vertical well refers to a well type whose designed trajectory follows a vertical line, with the wellhead and bottomhole having the same geographical coordinates. Its total angle change rate is generally no more than 3°/30m. The wellbore verticality is ensured by drill string assemblies such as packed hole assemblies and pendulum assemblies, and it is suitable for scenarios such as coalbed methane development where geological units need to be divided.

Vertical Well Drill String:The conventional drill string assembly consists of a rotary table rig + drill pipe + roller cone bit, which relies on the rigidity of the drill string itself to maintain verticality. Currently, the deviation prevention and straight drilling technology for vertical wells is mainly realized by improving the structural combination of the drill string:

Deviation prevention: Rigid packed hole assemblies, tower-type assemblies, and square drill collar anti-deviation assemblies are mainly used.

Deviation correction: Pendulum assemblies, flexible pendulum assemblies, eccentric weight drill collar assemblies, and downhole motor assemblies are mainly used.

Ⅱ. Application Scenarios

The application scenarios of vertical wells and directional wells are fully centered around three core needs: "resource distribution, surface conditions, and development efficiency". There is no absolute advantage or disadvantage between them, only differences in adaptability.

Vertical wells are a cost-effective choice for simple scenarios. Their core advantages are "low cost and high efficiency", so they are suitable for scenarios with simple surface and underground conditions and concentrated resources. No complex design is required—only the target formation depth needs to be determined, and the drilling can be planned along a vertical path. The drilling process is carried out at a constant speed throughout, with only regular well deviation angle measurements required and no frequent adjustments.

1. Conventional Oil and Gas Reservoir Development

When the oil and gas reservoir is directly below the wellhead, with a large reservoir thickness (>10 meters) and concentrated distribution, vertical wells can be drilled vertically to the target formation. The single-well productivity meets the demand, and there is no need for additional investment in directional costs.

2. Shallow Resource Exploration and Development

For shallow oil and gas reservoirs, groundwater, and geothermal resources with a burial depth of <1000 meters, vertical wells do not require complex trajectories and can quickly complete drilling and production.

3. "Preliminary Exploration" with Exploration Wells

In the early stage of oil and gas exploration, to obtain basic data such as underground formation lithology, porosity, and oil-gas bearing property, vertical wells (called parameter wells) are usually drilled. Due to their simple trajectory, vertical wells can more truly reflect the vertical formation sequence and provide a basis for the subsequent design of directional wells.

Ⅲ. Advantages and Disadvantages

Advantages

1.Low cost: The costs of equipment, construction, and maintenance are all lower than those of directional wells, and the single-well investment can be reduced by 30%~50%.

2.Simple technology: It has low technical requirements for the construction team, no need for professional directional engineers, and is easy to operate.

3.Short cycle: No frequent trajectory adjustments are required, and the construction cycle for the same depth is 30%~40% shorter than that of directional wells.

4.Low risk: The incidence of accidents such as wellbore collapse and pipe sticking is lower than that of directional wells (due to the simple trajectory, the drilling fluid circulation is more stable).

Disadvantages

1.Trajectory limitation: It can only develop resources directly below the wellhead and cannot bypass obstacles or cover scattered reservoirs.

2.Low development efficiency: For unconventional oil and gas reservoirs, the contact area between the wellbore and the reservoir is small, resulting in low single-well productivity (e.g., the daily output of vertical shale gas wells is only 10,000~20,000 cubic meters).

3.Large land occupation: To develop multiple scattered reservoirs, multiple vertical wells need to be drilled, which consumes a large amount of land platform resources.

Ⅳ.Conclusion

With the advancement of oil and gas development towards "unconventional, deep-layer, and offshore" areas, the application proportion of directional wells continues to increase. However, vertical wells are still irreplaceable. In scenarios such as conventional oil and gas reservoirs, shallow resources, and exploration wells, vertical wells will exist for a long time due to their advantages of "low cost and high efficiency". In small and medium-sized oilfields in some regions, vertical wells remain the main development well type.

The choice between the two is essentially a trade-off between "development needs and cost-effectiveness"—on the premise of ensuring the development target, vertical wells are selected for simple scenarios, and directional wells for complex scenarios, jointly supporting the efficient exploitation of global oil and gas resources.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported