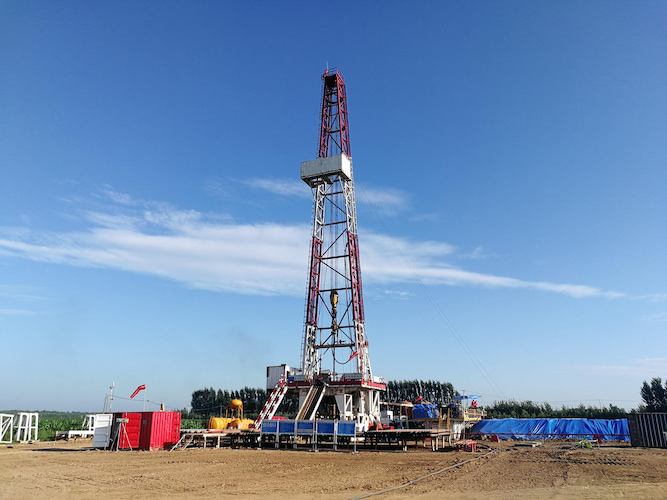

Exploring the WH1612 Fluid End of Drilling Pumps: The Core Power Source in Drilling Engineering

Dec 10, 2024

In petroleum drilling engineering, the WH1612 fluid end of drilling pumps is a crucial component specifically designed for petroleum drilling projects. Throughout the entire drilling operation, it undertakes the important task of converting mechanical energy into the pressure energy and kinetic energy of drilling fluid, serving as a core component to ensure efficient and safe drilling. It is just like a powerful heart, continuously providing essential power for the entire drilling operation and ensuring that the drilling work proceeds smoothly. Today, let's explore this important piece of equipment together.

Basic Structure and Components

The WH1612 fluid end of drilling pumps mainly consists of several key components such as the cylinder liner, piston/plunger, mud pump fluid end module,suction valve, discharge valve, and sealing devices.

The cylinder liner provides a stable space for the reciprocating motion of the piston or plunger. It is usually made of high-strength alloy steel, possessing excellent compressive and wear-resistant properties to cope with the harsh working environment and high-pressure impacts during the drilling process.

The piston and plunger are the core moving parts for converting mechanical energy into the pressure energy of the liquid in the fluid end. Since they need to perform high-speed and reciprocating movements within the cylinder liner, extremely high requirements are placed on the wear resistance, sealing performance, and rigidity of their materials. Generally, high-quality alloy materials are selected and undergo precise processing and special treatments to ensure that they can maintain good working conditions during long-term operation.

The mud pump fluid end module, which serves as the mounting carrier for the suction valve and the discharge valve, withstands tremendous pressure and liquid impact. It is manufactured using the upright integral forging process. This structure endows the mud pump fluid end module with extremely high strength and rigidity, effectively preventing deformation and rupture. Moreover, it improves the volumetric efficiency, enabling the drilling fluid to flow in and out of the cylinder liner more smoothly.

The suction valve and the discharge valve are like the "gatekeepers" of the fluid end, precisely controlling the inflow and outflow of the drilling fluid. They are usually made of high-strength alloy materials and equipped with high-quality sealing parts to ensure that they can remain tightly closed under high pressure differences, preventing the backflow of the drilling fluid, thereby guaranteeing the working efficiency and stability of the fluid end.

The sealing devices are the key defense lines to ensure the normal operation of the fluid end, responsible for preventing the leakage of the drilling fluid between various components. From the seals between the piston and the cylinder liner to those between the valves and the mud pump fluid end module, advanced sealing technologies and high-quality sealing materials such as rubber sealing rings and oil seals are adopted. These sealing parts have good high-temperature resistance, high-pressure resistance, wear resistance, and corrosion resistance properties, effectively reducing the leakage risk and improving the reliability and safety of the equipment.

Working Principle and Working Process

The working principle of the WH1612 fluid end of drilling pumps is based on the reciprocating motion of the piston or plunger. When the mechanical energy transmitted from the power end drives the piston to move backward, the volume inside the cylinder liner increases and the pressure decreases. At this time, the suction valve automatically opens under the action of the pressure difference, and the drilling fluid is smoothly sucked into the cylinder liner. As the piston moves forward, the volume of the cylinder liner gradually decreases, and the pressure rises rapidly. The suction valve closes, and the discharge valve opens. The high-pressure drilling fluid is then transported through the discharge valve into the drilling pipeline and further flows to the bottom of the well, completing one working cycle. Through continuous repetition of this cycle, the WH1612 fluid end of the drilling pump can continuously provide a stable high-pressure drilling fluid flow for the drilling operation, realizing the circulation of the drilling fluid in the well, carrying the cuttings from the bottom of the well to the ground, keeping the wellbore clean, and simultaneously providing cooling and lubrication for the drill bit to ensure the smooth progress of the drilling process.

Performance Characteristics

High-pressure and large-displacement capabilities: The WH1612 fluid end of drilling pumps is designed with outstanding high-pressure output capabilities, capable of meeting the requirements for high-pressure transportation of drilling fluid in complex drilling conditions such as deep wells and ultra-deep wells. Meanwhile, its relatively large displacement range can be flexibly adjusted according to different drilling operation requirements to ensure that the drilling fluid can circulate at an appropriate flow rate and improve drilling efficiency.

Good sealing performance: Thanks to the advanced sealing structure and high-quality sealing materials, the fluid end can still maintain good sealing performance under high-pressure working conditions, effectively reducing the leakage of drilling fluid. This not only reduces the risk of environmental pollution but also improves the overall working efficiency of the equipment and reduces the energy loss and maintenance costs caused by leakage.

High reliability and stability: By adopting high-strength materials and precise manufacturing processes, each component of the hydraulic end has excellent durability and anti-fatigue performance. Even during long-term and high-intensity drilling operations, it can operate stably, reducing the probability of malfunctions and providing reliable power support for drilling engineering, thus reducing the shutdown risks and maintenance costs caused by equipment failures.

Strong adaptability: It can be flexibly configured and adjusted according to different drilling techniques and formation conditions. Whether it is conventional drilling, directional drilling, or horizontal drilling, the parameters of the fluid end can be optimized to make it perfectly match the entire drilling system and adapt to various complex and changeable drilling operation requirements.

Maintenance and Service Points

Regular inspections: Establish a comprehensive regular inspection system to conduct a thorough inspection of all components of the fluid end. This includes checking the wear conditions of the piston and plunger, the sealing performance and opening flexibility of the valves, the scratching or corrosion status of the inner wall of the cylinder liner, and the aging and damage degree of the sealing parts. Through regular inspections, potential problems can be detected in a timely manner, and corresponding maintenance measures can be taken to avoid minor faults from developing into major ones.

Lubrication management: Ensuring good lubrication of all moving parts of the fluid end is the key to extending the service life of the equipment. Strictly follow the equipment operation procedures, regularly add an appropriate amount of special lubricating oil to components such as the piston, plunger, and connecting rod, and check the working status of the lubrication system to ensure that the lubricating oil passages are unobstructed. Meanwhile, pay attention to the quality and replacement cycle of the lubricating oil and replace deteriorated or contaminated lubricating oil in a timely manner to ensure good lubrication effects.

Cleaning and anti-corrosion: The environment at the drilling site is harsh, and the drilling fluid contains a large number of solid particles and corrosive substances, which are likely to cause pollution and corrosion to the components of the fluid end. Therefore, after each use, the fluid end should be cleaned in a timely manner to remove surface dirt and residual drilling fluid. For parts prone to corrosion, such as the mud pump fluid end module and piston rod, measures such as applying anti-corrosion coatings and installing anti-corrosion bushings can be taken to strengthen anti-corrosion protection and extend the service life of the components.

Replacement of wearing parts: The piston, cylinder liner, valve rubber, etc. are wearing parts, and their service lives are affected by multiple factors. Reasonably determine the replacement cycle of wearing parts based on factors such as the usage frequency of the equipment, working pressure, and properties of the drilling fluid.

Common Malfunctions and Troubleshooting Methods

Insufficient pressure: Possible causes may include failure of the piston or plunger seals, damage to the suction or discharge valves, blockage by foreign objects in the cylinder liner, etc. Check and replace damaged sealing parts and valves, clean out foreign objects in the cylinder liner, and ensure that all components are working properly to restore the pressure output of the fluid end.

Unstable flow: This may be caused by air leakage in the suction pipeline, poor sealing of the valves, uneven movement of the piston or plunger, changes in the viscosity of the drilling fluid, etc. To address these issues, carefully check the connection parts of the suction pipeline and repair air leakage points; check and adjust the valve seals; check the moving parts of the piston or plunger to ensure smooth movement and eliminate flow fluctuation phenomena.

Leakage problems: If leakage is found in the fluid end, first determine the leakage location. Common leakage points include areas around the sealing parts and valve connections. For leakage of sealing parts, replace the sealing parts in a timely manner; for leakage at valve connections, check and tighten the connection bolts or replace the sealing gaskets to ensure that the leakage problem is completely resolved.

As a core equipment component in drilling engineering, the performance quality and working status of the WH1612 fluid end of drilling pumps are directly related to the success or failure of the entire drilling operation.

The WH1612 drilling pump is the trademark and model of Cameron Company and has nothing to do with Tianjin Geostar Petroleum Equipment Co., Ltd. Tianjin Geostar mainly provides aftermarket spare parts for the WH1612 fluid end.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported