What is the F1600HL Electric Motor Driven Drilling Mud Pump?

Apr 25, 2025

The F1600HL Electric Motor Driven Drilling Mud Pump is a horizontal triplex single action piston pump, which is commonly used in equipment for oil and natural gas drilling and other fields. The following is the relevant introduction:

Ⅰ. Structural Composition

Power End

Frame: Welded with steel plates and stress-relieved, it provides support and an installation foundation for other components of the power end. There is an oil sump and an oil circuit system inside.

Gear Shaft: Usually composed of a gear, a shaft, and bearings, etc. The power output by the motor is first transmitted to the gear shaft.

Crankshaft: It is an integral casting made of alloy steel, which is precisely processed and inspected by flaw detection. The power is transmitted to the crosshead through the connecting rod, realizing the conversion from rotational motion to reciprocating linear motion.

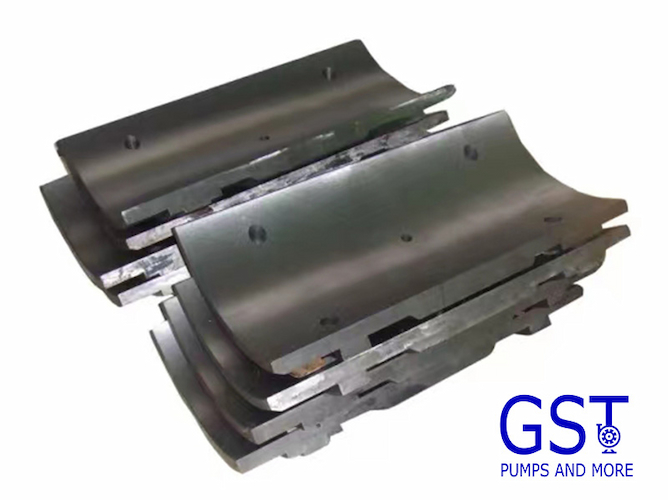

Mud Pump Crosshead: It plays the role of connecting the crankshaft and the piston, mainly composed of components such as the crosshead body, slide block, and pin shaft, guiding the movement direction of the piston.

Intermediate Tie Rod: The packing adopts a double-layer sealing structure, which can effectively prevent mud leakage.

Hydraulic End:

Mud Pump Fluid End Module: The material is an alloy steel forging. With an "L" shaped cylinder design and a straight-through cylinder structure, that is, a valve-on-valve structure, it reduces the volume of the Mud Pump Fluid End Module and improves the volumetric efficiency.

Valve Assembly: API 7# valves are used, with a high-pressure valve structure with unloading grooves, which can effectively reduce the opening pressure of the valve and increase the service life of the valve.

Mud pump Liner: Usually, a bimetallic cylinder liner is used. The inner lining is made of wear-resistant cast iron, and the inner hole surface has a high finish. It is sealed by cylindrical surface fitting and a rubber sealing ring and is tightened with a locking nut with anti-loosening function.

piston: A high-pressure piston resistant to high temperatures and oil-based drilling fluids is used, which has a good fit with the cylinder liner, ensuring the sealing performance and working efficiency of the mud pump.

Suction and Discharge Manifold: A suction air chamber is usually installed on the suction pipeline to stabilize the suction pressure and reduce pressure fluctuations; a discharge air chamber, a shear pin safety valve, and a discharge strainer are respectively installed at the discharge port.

Air Chambers: Including the suction air chamber and the discharge air chamber, which are filled with gas at a certain pressure. Their main function is to effectively reduce the pressure fluctuations in the suction and discharge systems, thus obtaining a more uniform liquid flow.

Other Auxiliary Components:

spray Pump Assembly: It includes components such as a spray pump, pipelines, and spray nozzles, which supply cooling and lubricating fluid (water) to the cylinder liner and piston of the hydraulic end for cleaning, cooling, and lubrication.

Lubrication Mechanism: The lubricating oil is delivered to the working surfaces of components such as gears and bearings at the power end through an oil pump to form an oil film, reducing the friction coefficient and wear.Safety Valve: Such as a shear pin type high-pressure safety valve. When the pump outlet pressure exceeds the set value, the safety valve opens to release the pressure and protect the equipment.

Ⅱ. Functions

Circulating Drilling Fluid: During the drilling process of deep and ultra-deep oil wells, by continuously circulating the drilling fluid, it flushes the bottom of the well and carries the cuttings back to the surface, ensuring the smooth progress of the drilling work.

Cooling and Lubrication: It provides cooling and lubrication for the drill bit, reducing the temperature of the drill bit during the drilling process, reducing wear, and extending the service life of the drill bit. At the same time, it helps to increase the drilling speed.

Reinforcing the Wellbore: It enables the drilling fluid to form a mud cake on the wellbore wall, playing the role of reinforcing the wellbore wall and preventing the wellbore from collapsing.

Ⅲ. Performance Advantages

Comply with Standards: It is produced in strict accordance with API Spec 7K "Specification for Drilling and Well Servicing Equipment" and undergoes factory tests according to this standard, ensuring that the product quality and performance meet international standards and are suitable for various complex drilling conditions.

High Pressure and Large Displacement: The maximum working pressure can reach 52MPa, and the displacement can reach 51.8L/s, which can meet the requirements of new drilling processes such as deep wells, ultra-deep wells, large-displacement horizontal wells, and high-pressure jet drilling, providing strong power support for drilling operations.

Good Priming Performance: It has a long stroke and can be used at a low stroke rate, effectively improving the priming performance of the mud pump. Furthermore, it extends the service life of the vulnerable parts at the hydraulic end, reducing the maintenance cost and downtime of the equipment.

Advanced and Compact Structure: The overall structure is advanced and compact, with a small volume, which is convenient for installation and transportation and can adapt to different drilling sites and operating conditions.

Long Service Life of Vulnerable Parts: With a long stroke and the ability to operate at a low stroke rate, it effectively improves the priming performance of the mud pump, thus extending the service life of vulnerable parts at the hydraulic end such as cylinder liners, pistons, and valves, reducing the maintenance cost and downtime of the equipment.

Easy Maintenance: The power end and the hydraulic end adopt an independent structural design, which is convenient for inspection, maintenance, and repair. The vulnerable parts at the hydraulic end such as cylinder liners, pistons, and valves are easy to replace without having to disassemble too many components, improving the maintenance efficiency.

Ⅳ. Application Areas

Oil and Natural Gas Drilling: It is suitable for onshore and offshore oil and natural gas drilling platforms, providing high-pressure mud for the drilling process and meeting the drilling requirements under different depths and complex geological conditions.

Geothermal Drilling: It can be used in the drilling operations for geothermal resource development, pumping out the hot water or mud in the geothermal wells to realize the exploitation and utilization of geothermal resources.

Geological Exploration Drilling: In the field of geological exploration, it is used for drilling geological structures, obtaining core samples, and other operations, providing data support for geological research.

Ⅴ. Transmission Process

The power transmission process of the power end of the F1600HL Electric Motor Driven Drilling Mud Pump is as follows:

Motor Power Output: After the motor of the electric drive system is started, it generates rotational power. The output shaft of the motor is connected to the gear shaft, transmitting the power to the gear shaft.

Gear Transmission: The gear on the gear shaft meshes with the bull gear. The rotation of the gear drives the bull gear to rotate. The bull gear is closely combined with the bull gear shaft through a key connection or other fixing methods, and the bull gear shaft rotates with the bull gear, thus transmitting the power from the gear shaft to the bull gear shaft assembly.

Crankshaft Rotation: The rotational motion of the bull gear shaft is transmitted to the crankshaft, driving the crankshaft to rotate. The crankshaft is usually an integral casting made of alloy steel, which is precisely processed and inspected by flaw detection.

Connecting Rod Transmission: The crankshaft is connected to the crosshead through the connecting rod. The rotational motion of the crankshaft is converted into the reciprocating linear motion of the crosshead through the connecting rod. During the movement of the connecting rod, one end moves in a circular motion with the crankshaft, and the other end drives the crosshead to move in a reciprocating linear motion in the slideway.

Crosshead Driving the Piston: The crosshead is connected to the intermediate tie rod, and the intermediate tie rod is then connected to the piston. The reciprocating linear motion of the crosshead is transmitted to the piston through the intermediate tie rod, making the piston move reciprocally in the cylinder, thus providing power for the hydraulic end and realizing the suction and discharge of the mud.

The power transmission process of the hydraulic end of the F1600HL Electric Motor Driven Drilling Mud Pump is as follows:

Piston Reciprocating Motion: The crosshead at the power end drives the piston to move reciprocally in the cylinder through the intermediate tie rod. When the piston moves backward, a negative pressure is formed in the cylinder; when the piston moves forward, the mud in the cylinder is compressed, and the pressure increases.

Suction Process: When the piston moves backward, the pressure in the cylinder decreases to form a vacuum. Under the action of atmospheric pressure, the mud pushes open the suction valve and enters the cylinder. The suction air chamber can stabilize the suction pressure and reduce pressure fluctuations, enabling the mud to enter the cylinder more smoothly.

Discharge Process: When the piston moves forward, the mud in the cylinder is compressed, and the pressure increases. The suction valve closes, and the discharge valve is pushed open. The mud is forced out of the cylinder and is transported to the drill pipe through the discharge manifold and then sent to the bottom of the well. The function of the discharge air chamber is to reduce the pressure fluctuations in the discharge system, making the discharged mud flow more stable.

Ⅵ. MaintenanceDaily Maintenance

Check Operating Parameters: Check the operating parameters of the pump every day, including pressure, flow rate, motor current, and voltage, etc., to ensure that these parameters operate within the specified range. If any abnormal parameters are found, stop the machine immediately to check the cause.

Check the Lubrication System: Before each start-up and during operation, check the oil level, oil quality, and oil temperature of the lubricating oil at the power end. The oil level should be maintained within the specified scale range. The oil quality should be clean without impurities and emulsification. Generally, the oil temperature should not exceed the specified value (usually 60 - 70℃). Regularly replenish or replace the lubricating oil, and at the same time, check the working status of the oil pump to ensure the normal oil supply of the lubrication system.

Check the Cooling System: Check the working condition of the spray pump to ensure its normal operation, providing good cooling and lubrication for the cylinder liner and piston at the hydraulic end. Check whether there are blockages, water leaks, and other problems in the cooling water pipeline, and clean the blockages and repair the water leakage points in a timely manner.

Check the Sealing Condition: Observe the sealing parts of the pump, including the cylinder liner seal at the hydraulic end, the valve seat seal, and the shaft seal at the power end, etc., to see if there is any mud leakage. If leakage is found, find out the cause in time and replace the damaged sealing parts.

Clean the Equipment: Regularly clean the mud, oil stains, dust, and other sundries on the surface of the pump body to keep the equipment clean. Pay special attention to cleaning the dust on the motor cooling fins to ensure good heat dissipation of the motor.

Regular Maintenance

Replace Vulnerable Parts: According to the running time and wear condition of the pump, regularly replace vulnerable parts such as pistons, cylinder liners, valve seats, valve plates, and crosshead sliders, etc. It is generally recommended to check and replace these vulnerable parts after running for a certain number of hours (such as 500 - 1000 hours).

Check Components at the Power End: Regularly open the inspection cover of the power end, check the wear condition of components such as gears, crankshafts, and connecting rods, measure the fit clearance of each component. If the wear exceeds the specified range, repair or replace it in time. At the same time, check the tightness of each connecting bolt to ensure a firm connection.

Check Components at the Hydraulic End: Regularly disassemble the valve box at the hydraulic end, check the sealing performance and wear condition of the valve seat and valve plate, and clean up the sundries and mud deposits in the valve box. Measure the wear of the cylinder liner. If the inner diameter wear of the cylinder liner exceeds the specified value, replace it in time.

Calibrate the Safety Valve: Regularly calibrate the safety valve to ensure that it can be reliably opened and closed within the specified pressure range to protect the safety of the equipment. Generally, the safety valve should be calibrated every six months or once a year.

Maintain the Electrical System: Regularly check the insulation resistance of the motor to ensure good insulation. Clean the dust inside the frequency converter, control cabinet, and other electrical equipment, and check whether the connections of each electrical component are loose. If loose, tighten them in time.

Maintenance in Special Situations

Long-term Shutdown: If the pump needs to be shut down for a long time, comprehensive maintenance and protection should be carried out. First, empty the mud in the pump and rinse the hydraulic end and pipeline system thoroughly with clean water to prevent the mud from settling and solidifying. Then, apply anti-rust oil to the exposed parts of the power end and the hydraulic end to prevent rust. Finally, park the pump in a dry and well-ventilated place and turn the pump shaft regularly to prevent the parts from rusting and jamming.

After Fault Repair: After the pump malfunctions and is repaired, focus on checking and testing the repaired parts. Ensure that the repaired parts are correctly installed and firmly connected, and that all performance indicators meet the requirements. At the same time, conduct a trial run of the entire pump unit, check whether the operation is stable and whether the parameters are normal. Only after confirming that there are no problems can it be put into formal use.

Read More

Language :

Language : English

English Русский

Русский عربي

عربي

GET A QUOTE

GET A QUOTE

IPv6 network supported

IPv6 network supported